Machines for testing finned batteries are characterised by a process which is generally divided into two stages:

- Testing under pressure, up to 5 MPa (50 bar), conducted with dry air or nitrogen, to meet pressure-resistance requisites in accordance with applicable standards. This test also enables interception, in the eventuality, of macro-leaks without running the risk of polluting the measurement circuit and instruments with helium.

- Fine leaktesting, performed with helium, with limited pressure values, from 500 kPa to 1.5 MPa (5÷15 bar), capable of detecting extremely small leaks due to optimal sensitivity of measurement systems and direct proportionality between leak flow and pressure leap generating this flow.

The testing process was finalized on the basis of an assessment of the experiences of users and awareness that medium-to-big leaks are more likely than fine leaks.

While highly sensitive (capacity to arrest coolant leaks of less than 0.5 g/year), these machines are also characterised by extremely rapid process capacities, up to 240 units/hour, or more, for the versions with double chambers, placed side by side.

|

|

|

|

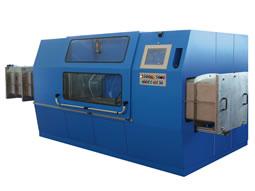

Semi-automatic machines for leaktesting of heat exchangers with finned core - batteries. |

||

|

|

|

|

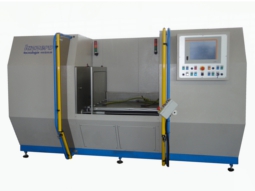

Semi-automatic machines for leaktesting of large exchangers. The helium testing technique is found to be reliable, and the reach-out of the process takes in testing of increasingly large exchangers. |

||

|

|

For leaktesting of large exchangers, increasingly, the machines produced function with modular chambers which can be lengthened by extension components.

|

||

|

Semi-automatic machine for leaktesting of heat exchangers for domestic gas boilers. In this case, while testing is performed under pressure for mechanical stress with simple air, leaktesting is performed in conformity with the UNI-EN13185.A/1 ‘vacuum’ standard. |

||