Various solutions are available for testing under pressure and leaktesting of braze-welded plate heat exchangers. The tested items are characterised by the presence of 2 or 3 or up to 4 independent circuits. They are tested individually and sequentially by means of a test performed under pressure, for which 10 MPa (100 bar) may be attained, with air. This is followed by helium leaktesting, while controlling seal between circuit and circuit, and the seals of these circuits with respect to the outer environment (highly sensitive).

Testing is generally objectively confirmed by mechanical mark stamping. Automation entails use of an advanced HMI graphic interface capable of pooling all test information in recipes, which are graphically configurable and can be called up, generally by bar code scanning. The control PLC/PC also enables connection with the corporate electronic data processing network for process data collection.

Complete lines with more rooms in order to perform various functional tests for the optimization of time.

|

|

|

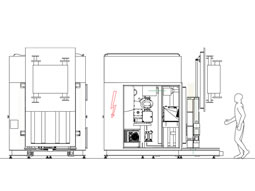

Systems with one or two test chambers, with system for pressurization and recovery of leaktesting helium built-in.

|

|

|

Test machine for testing under pressure and leaktesting for large exchangers. The machine includes a double system for loading of, and support for, the tested units, enabling performance of loading and unloading operations, in-process hermetic sealing during the in-chamber testing process. The equipment for supporting the tested units can be raised in order to enable practical and safe assembly of the equipment for hermetic sealing.

Small braze-welded plate aluminium exchangers are tested in dedicated machines with small chambers, for optimization of the testing processes for the two or more circuits.